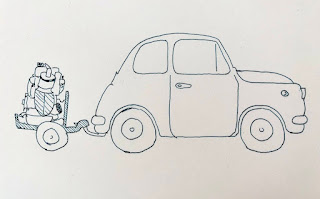

Electric conversion for my Fiat 500 – day 6

Having bought 5m of aluminium T bar, today I'll build a frame to hold the batteries and the controller in the engine bay.

I will also build a support to hold the motor in position and link it to the original engine shock absorber.

The 5m weights about 2.5 Kg, and I foresee to use it almost all of it.

STEP 50

In Fusion 360 I have designed a profile that matches the lower back shape of the motor. It was quite easy as I've found a 3D model of the exact motor I am using on the internet.

STEP 50.1

Printed the profile in a 3D printer.

I've used such prop to check it would fit on the motor and to trace the shape on a bar of aluminium.

STEP 51

Armed with an hacksaw and a metal file, I've trimmed the aluminium profile to match my 3D printed prop.

The idea is to use threaded bars to keep the profile in position and link it to the original engine shock absorber that is present in the Fiat 500.

To link the threaded bars to the profile I have shaped 2 extensions made out of aluminium block.

STEP 52

I have finished the profile on a mill drill at the hack space in town to get a better finish and to drill the 6 holes that will then push and pull the profile against the motor.

STEP 53

Saw to size 4 threaded bars. 2 will be used to link the shock absorber to the profile and hold the motor vertically and 2 will be used to lean the profile against the motor.

STEP 54

Saw, drill and file the bars to build the frame.

I need:

2 bars 90cm long. - These will work as horizontal beams.

2 bars 43 cm long. - These will work as a longitudinal beams.

2 bars to make the vertical posts.

STEP 55

Hack and modify 2+3 aluminium extruded profiles to make the support to connect the frame to the body of the car.

2 will lock on near the rear bumpers to support the vertical posts, and I've just shaved off one corner of the profile to make it fit better.

3 extruded profiles will not require any modification. These will dock against the back of the back seats.

I had these extruded profiles around the house, so that's another item I recycled.

STEP 56

Tight all the nuts, threaded bars and bolts to put together the motor support profile.

STEP 57

Tight the nuts to the 2 treaded bars that hold the motor vertically linking it to the shock absorber.

STEP 58

Drill 3 holes in the back panel of the back seats. See image for positioning.

STEP 58

Bolt together all the aluminium bars and the extruded profiles.

Comments

Post a Comment